Complete Opener Line up

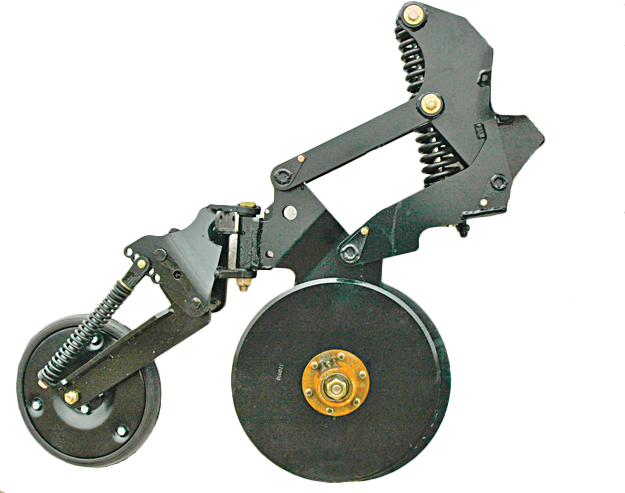

Model 8600 Series Gent

Designed to have our patented undercut technology. Superior seed placement over other competitor disc drills. Works well in heavier residue and also firmer soil conditions.

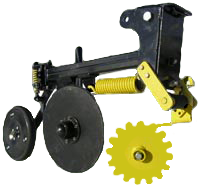

Model 4612

Designed with parallel link trip system. A traditional double disc but with a superior bearing system and a 1 ¼” offset blade arrangement compared to the traditional ¾” or even zero offset. Works great in loose soils and moderate residue cover. Best opener for real muddy conditions.

Model 3612

Designed to be the simplest double disc while at the same time to be a very robust opener. Still has our superior bearing system but does not have a parallel link trip system.

Why choose K-Hart Double Disc Openers?

1. Why choose disc openers over knife openers or spoons for direct seeding?

| Disc openers (PROS) | Knife openers/spoons (CONS) |

| Low horsepower requirement | Higher horsepower requirement |

| Lower fuel costs | Higher fuel costs |

| Higher seeding speeds while still maintaining a smooth soil seedbed | Higher seeding speeds leave the seedbed very rough relating to higher repair bills for following field operations by traveling over rough ground. |

| Cannot pull up rocks | Great at pulling up rocks |

| Seed through high standing stubble. Can use combine stripper headers or straight cutter headers and cut as high as you like. No restrictions. | Monitor how high you cut with your combine header. As a rule of thumb, you should not cut any higher than the width or spacing of your seeding tool. |

| Seed with the least amount of soil disturbance reducing the potential of germination of weed seeds | Promotes more weed germination than a disc opener |

| Seed into vine crop stubble with no hang-ups Example: pea stubble | Vines hang on to openers causing bunching in the field. |

| Seed into wetter soil conditions | Need drier soil conditions to prevent plugging of openers |

2. Why choose K-Hart double disc openers over competitors' double disc openers?

| K-Hart double disc openers | Competitors' double disc openers |

| 5206 series double roll ball bearings with triple lip seals on both inside and outside Improved design, better than using tapered roller bearings. | Smaller, inferior single ball bearing with single lip or double lip seal. They use small 204 or 205 series bearings. |

| The largest and best-protected bearing system in the industry. Besides the triple lip seal protecting both sides of the bearing, you now have the option of greasing this bearing twice a year if you so choose. | Inferior single ball bearing with single lip or double lip seal. They use small 204 or 205 series bearings. Usually non greaseable. |

| 1 ¼" offset leading blade which allows the opener to cut through residue and soil better than nose to nose blades. Easier penetrating. | Nose to nose blades, greatly increased the chance of hair pinning and harder to push in the soil. |

| 16" & 17" Heavy Duty blades made with the latest technology and material available to ensure long-lasting durability. | 14" or sometimes 15" lighter material blades. |

| Largest selection of packers on the market | Limited packer choices |

| Built Heavy Duty, specifically designed for no-till conditions but can also work in pre-worked ground | Designed more for lighter duty no-till work. |

3. Why choose K-Hart double disc openers over single disc openers?

| K-Hart double disc openers | Competitors' single disc openers |

| K-Hart disc openers have a less complicated design having fewer moving parts | More moving parts. Depth wheels etc. to plug up with mud. |

| Can work no-till and pre-worked ground | Single disc openers have problems keeping the disc turning in loose soils |

| Less horsepower required for blades to roll straight ahead | Single disc openers run on angles requiring more horsepower |

| Minimum residue disturbance | Most single disc openers use a side depth wheel. This wheel pulverizes the soil it rides on, making the soil prone to wind erosion |

Specifications

(Based on Model 4612 and Model 8612)

| 9" Spacing | |||||

| Width (ft) | Sections | Number of Openers | Approximate Weight base unit (lbs)* | ||

| Frame | Openers | Total | |||

| 34 | 3 | 45 | 10300 | 7155 | 17455 |

| 42 | 3 | 57 | 10700 | 9063 | 19763 |

| 50 | 3 | 67 | 16250 | 10653 | 26903 |

| 56 | 5 | 74 | 20700 | 11766 | 32466 |

| 66 | 5 | 88 | 21300 | 13992 | 35292 |

| 76 | 5 | 100 | 21700 | 15882 | 37582 |

| 10" Spacing | |||||

| Width (ft) | Sections | Number of Openers | Approximate Weight base unit (lbs)* | ||

| Frame | Openers | Total | |||

| 34 | 3 | 41 | 10300 | 6519 | 16819 |

| 42 | 3 | 52 (9.75" spacing) | 10700 | 8268 | 18968 |

| 50 | 3 | 60 | 16250 | 9540 | 25790 |

| 56 | 5 | 66 | 20700 | 11653 | 32353 |

| 66 | 5 | 80 | 21300 | 12720 | 34020 |

| 76 | 5 | 90 | 21700 | 14300 | 36000 |

| 12" Spacing | |||||

| Width (ft) | Sections | Number of Openers | Approximate Weight base unit (lbs)* | ||

| Frame | Openers | Total | |||

| 34 | 3 | 34 | 10300 | 5406 | 15706 |

| 42 | 3 | 42 | 10700 | 6678 | 17378 |

| 50 | 3 | 50 | 16250 | 7950 | 24200 |

| 56 | 5 | 56 | 20700 | 8904 | 29604 |

| 66 | 5 | 66 | 21300 | 10494 | 31794 |

| 76 | 5 | 76 | 21700 | 12000 | 33700 |

| Width (ft) | Frame Depth (ft) (with openers, from hitch) |

Transport Width (ft) (with openers) |

Transport Height (ft) (with openers) |

| 34 | 24 | 20'6" | 13'3" |

| 42 | 24 | 20'6" | 17'3" |

| 50 | 25'9" | 24'3" | 17'3" |

| 56 | 25'9" | 24'3" | 13'9" |

| 66 | 25'9" | 24'3" | 18'6" |

| 76 | 25'9" | 24'3" | 18'6" |

* Weights are theoretical and approximate and will vary with options selected. Additional weight can be added. All specifications are subject to change without notification.