DISC OPENERS

Model 4612

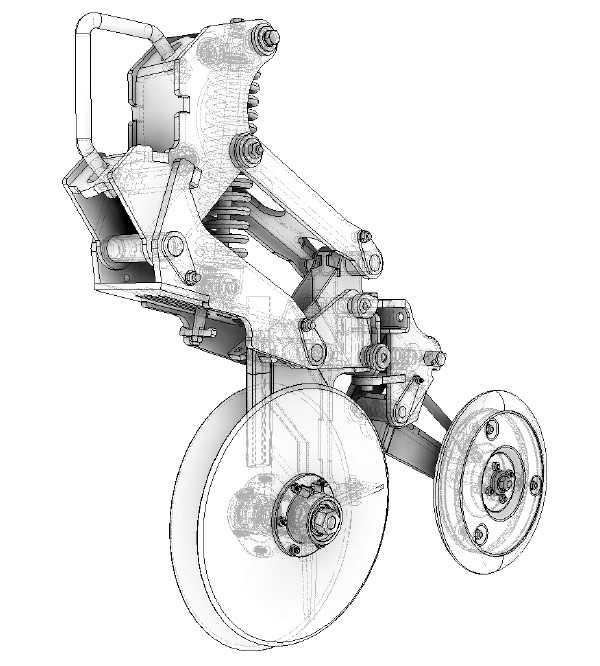

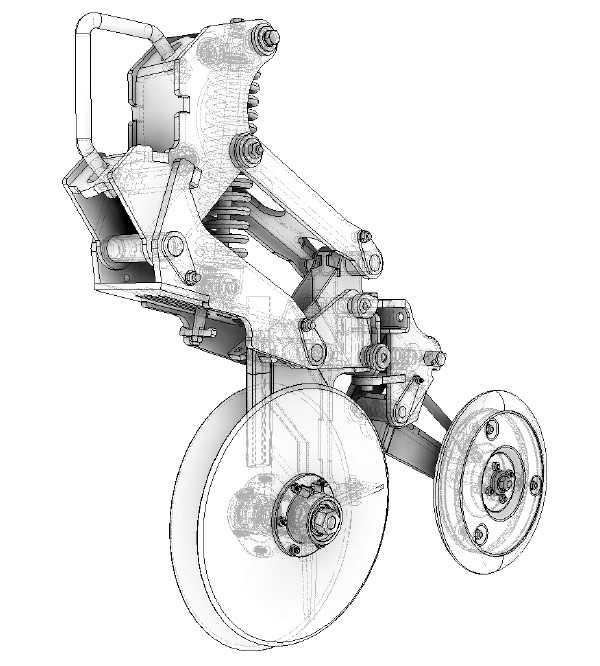

Parallel link design

We have combined all the top features of all previous K-Hart parallel link models into the 4612 series. Model 4612 features a parallel trip linkage giving way for straight up and down travel of 8 inches and can be adjusted to six different down pressure settings without tools. Simply pull down on a T-handle and sliding the main down pressure spring to the desired hole, downforce pressure on the blades can be adjusted from 120 lbs. to over 800 lbs. in order to match different soil conditions.

The K-Hart deluxe packer is what really sets us ahead of competitor’s disc openers. First, with no tools, packer depth can be adjusted in ¼ inch increments for controlling the depth at which the discs will be placing the seeds. The packer assembly also offers another K-Hart exclusive design. When in working position, the packer assembly rests against an adjustable cam stop to give positive disc depth control. However, in spots where the opener rises to go over a rock, the packer is spring-loaded in the opposite direction and stays on the ground maintaining packing pressure. This spring-loaded packer force is also adjustable from 20 pounds to 150 pounds. The packer assembly can either swivel or be restricted from swivelling. A variety of packer wheels are available.

We would also like to bring to your attention to disc size and disc bearings. We offer 16‑inch diameter discs and the disc openers that travel in the tractor wheel marks, have 17‑inch discs. The discs are larger than most competitors, allowing longer field life before they will need replacing. Right hand and left-hand blade arrangements ensure that the drill tracks squarely down the field.

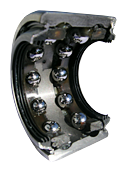

What really sets us apart from other disc openers is our bearing design that supports our discs. Our 5206 series bearing is a triple lip sealed bearing that now has the additional capacity of being greased if the customer chooses to do so. This is accomplished by having grease journal inside our cast hub and an external. When we say the bearing can now be greased, we mean twice a year; and you cannot hurt our bearing by over greasing it. Greasing twice a year should allow this bearing to last forever. For the customers that choose not to grease, this bearing will still give several years of maintenance-free service.

Available options:

- All opener models can be fitted with K-Hart’s optional residue managers. No other residue manager on the market offers all of the following features: adjustable blade angles, an exclusive adjustable spring for different down pressures and a lock-up tab when the residue manager is not required. It also has a proven bearing system that will outperform most bearing systems, giving years of trouble-free operation. Our steel residue manager blades are made with special wear-resistant material for exceptional durability. The exclusive K-Hart trip assembly helps eliminate damage when tripping over rocks allowing up to 10” of trip travel.

- All models can be equipped with optional mud scrapers for cleaning between the discs.

- All models can be equipped with our many different packer profiles.

- All models can be equipped with K-Hart fertilizer banders when mounted on a K-Hart toolbar.

Disc Bearings

(One of K-Hart's best-kept secrets that we are now letting you in on!)

While many competitors' drills use light 204 or 205 series disc bearings which lack axial and thrust support, K-Hart uses a bearing specifically design for tough and dirty seeding conditions. Our 5206 series bearings offers a sealed double row ball, triple lip seal that surpasses any other disc bearing on the market for reliable long term performance.

Stored position for inter-row fertilizer banders.

Working position for inter-row fertilizer banders.